Wind turbine gearboxes are typically designed to last 20 years; however, the industry knows that the majority do not live up to these expectations. In fact, most fail within the first 7-10 years of operational life, resulting in costly gearbox exchanges, ranging between $150,000 and $300,000 per turbine.

It’s know that the problem lies beneath the surface in the materials of the critical components, the bearings and gears. Gearbox configurations, depending on type, have approximately 22 bearings, each with an L10 design life of 20 years. However, loading and operational conditions, lubrication viscosity and surface roughness are just a few of the factors that impact wear, rolling contact fatigue and failure mechanisms that cause premature failure.

Traditionally, operators rely on data from temperature and vibration sensors, condition monitoring systems and SCADA to identify bearing and gear failures in the field. However, the accuracy of the sensor data alone is questionable, and by the time a noticeable difference in temperature or vibrations is detected in the CMS or SCADA data, the damaged bearing or broken gear tooth is wreaking havoc on secondary components within the system.

Operators are beginning to contract with software service providers to determine the failure rates of their mechanical components to plan for operations and maintenance events. Most big data solutions calculate the wear rate from either macroscale inputs from a Finite Element Analysis model or empirical equations that generate a deterministic bearing life. While these solutions can be useful, tribology-related failures are probabilistic in nature and very complex.

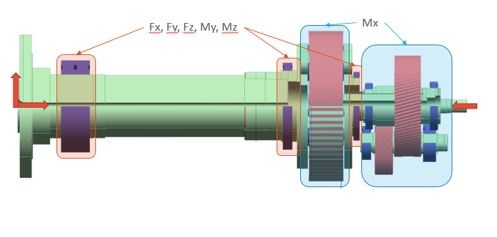

In order to determine probabilistic failures and long-term prognostics for the major systems and critical components within the turbine, a system model needs to be created of each unique asset. True prognostics combines materials science and physics-based wear modelling with contact mechanics and lubrication models to simulate the early manifestation of damage within the microstructure of the materials. The output from the digital model predicts the long-term failure rate of the gearbox by critical component. One the materials-based digital model is created, it’s integrated with the SCADA system to identify any operational condition or loading event that may alter the long-term health of the asset.

For more information download the presentation on Validating DigitalClone Prognostics Models.