DigitalClone

for In-Situ Monitoring

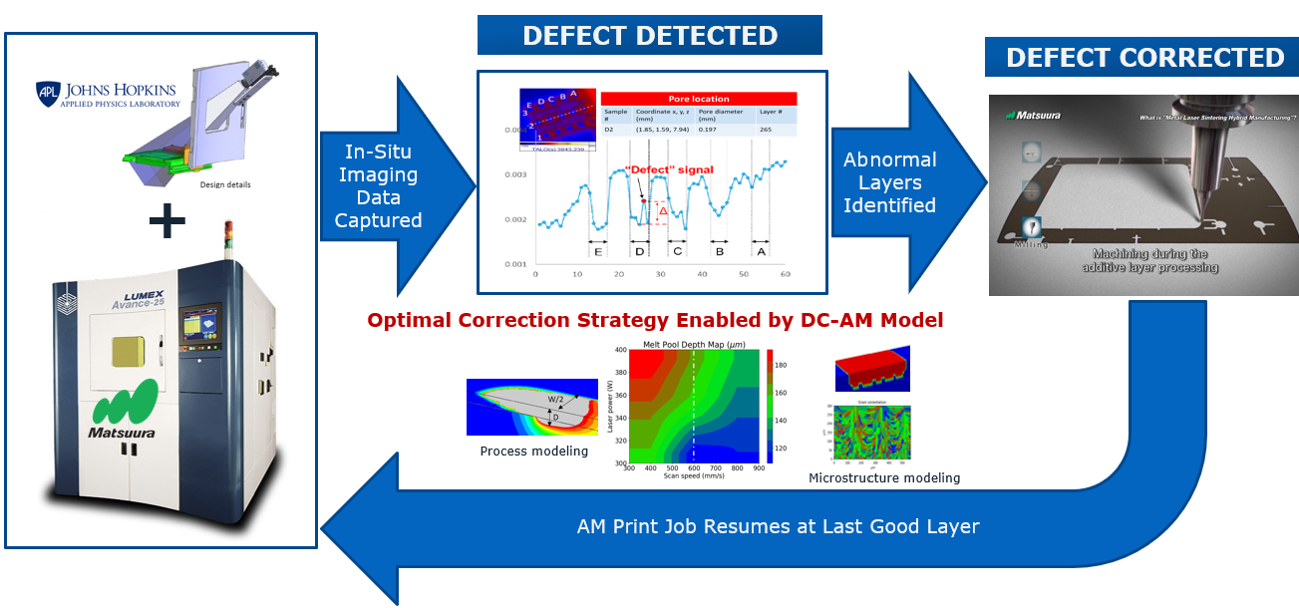

DC-IM is a quality assurance system for metal additive manufacturing process. It is customizable for any printer model in partnership with the manufacturer. DC-IM currently leverages Matsuura hybrid metal AM machine and in-situ sensing capability to monitor and correct defects in real time, assuring the highest quality of as-printed metal parts. In the DC-IM system, each printing layer is monitored by using an infrared sensor, followed by Sentient’s proprietary real-time data analysis algorithm to determine the acceptance of layer quality at end of each printing. Bad layers are machined off and re-built based on Sentient’s optimized strategy. This detection and correction process will repeat until the entire component is built.

Request DemoCore Functionality

DC-IM Modeling Results

How Does It Work?

DC-IM provides an in-process defect monitoring and correction technique for AM to improve repeatability for geometric dimensions, material properties, and quality.

This process can be used in quality assurance plans to obtain the confidence needed for high-quality manufacturing.

DigitalClone can

- Monitor for defects during the build process using an infrared (IR) camera

- Correct defects using optimized AM process parameters through advanced modeling and simulation

- Reduce prototype optimization sample builds from dozens to just a handful

- Accelerate process optimization timelines from weeks/months to days

- Enable faster implementation of AM-based designs