Automotive

Perform computational fatigue simulation, to accelerate the design process and reduce the cost of prototype physical testing in product development and validation

Request DemoAccelerating Design Schedules by

Taking a First Principles Approach

Sentient takes a first principles approach to predict the life of mechanical systems. Data science solutions are not able to detect existing damage or damage initiation. DigitalClone allows users to analyze what combination of design factors, material characteristics and usage profiles are going to result in the first crack occurring in that component. By integrating first principles into designs and using predictive solutions, users can identify potential threats to their assets and fleet.

Using Sentient’s Multiscale Framework

Sentient’s multi scale framework to assess the life impacts from the most basic material level where the physics-based models are more predominate up to the enterprise level where we leverage AI and ML algorithms to train the models with inputs from the vast data streams that are being collected across the fleet.

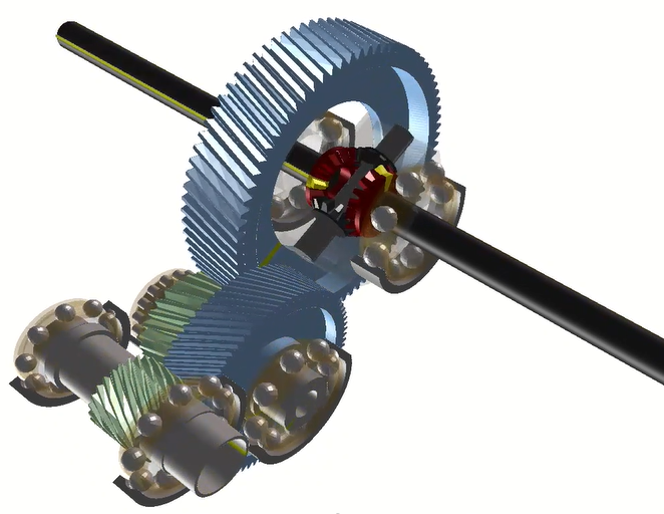

Virtually Testing to Predict the Component Life

DigitalClone builds material microstructure models to understand fatigue failure, as well as surface traction models to understand the tractions and stresses on the materials. Through virtual loading, DigitalClone can predict the material response through damage accumulation. Once the models are complete, the operational loads are applied to the system and life outcomes of the designs are predicted.

Reduce Risk, Cost & Uncertainty with long-term visibility of component remaining useful life

The Approach

The detailed nature of Sentient’s approach allows for virtual exploration of the effect of many different design variables on the expected reliability of the system.

Geometry, lubricants, materials and manufacturing specifications can be evaluated with respect to impact on part reliability.

This ability to efficiently explore a wide trade space enables optimizations that can lead to improvements in

o production costs

o production schedule

o operations and sustainment costs

o platform availability

o allowed operating envelope

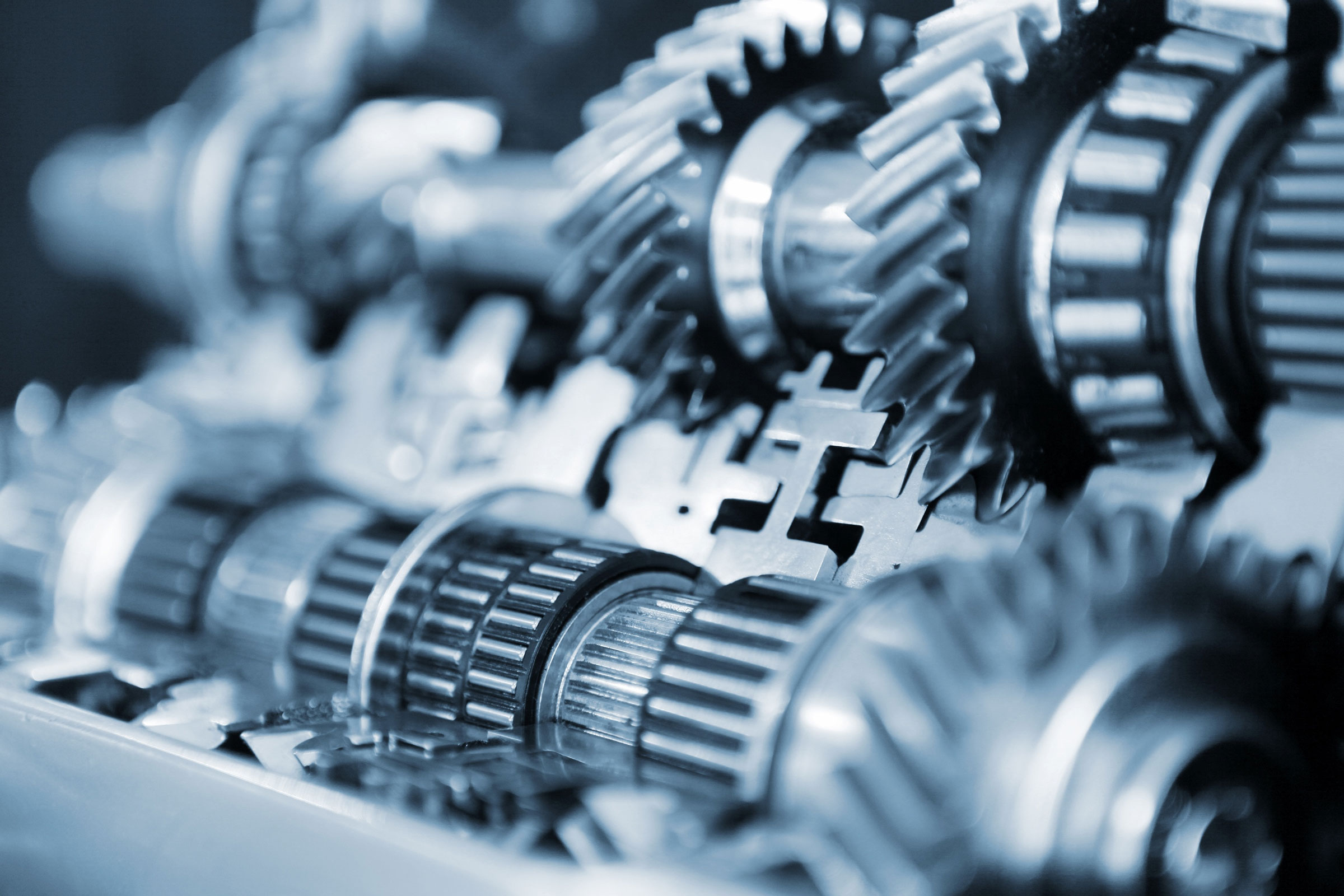

Manufacturers

Computationally simulate competing technologies and designs to make data driven decisions.

Evaluate risk when optimizing designs to reduce size, weight and cost.

Utilize DigitalClones for future prognostics for a fleet of vehicles, critical systems and life limited components.

Suppliers

Reduce the time to design, qualify and supply transmission systems with specific OEM criteria.

Quickly turn proposals around and maintain design promises.

Optimize material selection and manufacturing processes to achieve better performance, reduced weight and less cost.