Our Mission

is to lower the cost of operating mechanical equipment through the digitalization of assets, providing digital twins to an ecosystem of operators and suppliers to achieve life extension, sustainability and reliability.

Sentient Science

Industry leader in advanced prognostic solutions

Expertise in tribology, physics and data science

Award winning solutions in Additive Manufacturing, Aerospace & Defense, Automotive and Wind

DigitalClone and Industrial SaaS Powered by Physics and Data Science

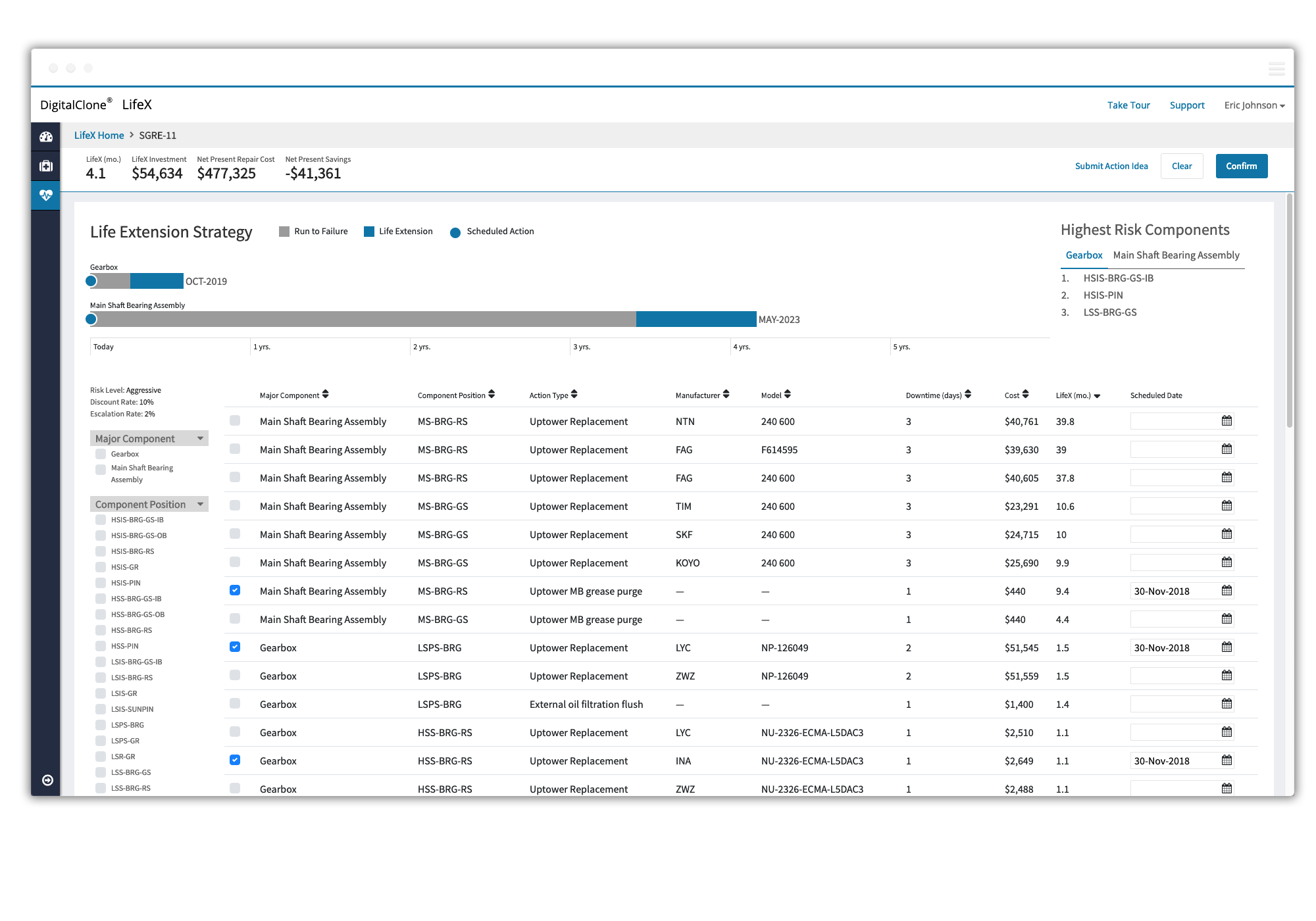

Our applications are built off our platform which uses physics and data science based prognostics to reduce the operational costs of fielded assets by improving sustainability and reliability.

View Our Platform Offerings

Our SaaS Platform Solves Business Problems with Science

DigitalClone technology is transferable to any industrial or transportation application as it is rooted in simulating the failure process (lifecycle) over the lifetime of the asset under its unique operating conditions. By understanding how failure initiates and propagates in the asset, prescriptive life extension actions can be taken to mitigate risk of unplanned failure events.

Over 20 Years of Research and Development

Since 2001, Sentient Science has been devoted to extending remaining useful life of fielded assets and optimizing new product design and testing. It is this mission that has led to over 20 years of research and$22 million of competitive research and development funding for research and to validate our DigitalClone technology.

Awards

|

Year |

Award by Agency |

Phase |

Program |

Topic Code |

Award Title |

|

2023 |

Department of Defense Air Force |

Phase II |

SBIR |

AFX236-DPCSO1 |

In-Situ Additive Manufacturing Tracking and Modification with DC-IM |

|

2022 |

Department of Energy |

Phase I |

SBIR |

14A |

An Integrated Software Package for Studying Structure-Property-Processing Relationships in Material Systems |

|

2022 |

Department of Defense |

Phase III |

SBIR |

N/A |

Sentient Science DigitalClone Demo for EDGE 22 |

|

2021 |

Department of Defense |

Phase II |

SBIR |

A19-140 |

Rolling/Sliding Contact Fatigue Life Physics and Modeling |

|

2020 |

Department of Defense |

Phase I |

SBIR |

A19-140 |

Rolling/Sliding Contact Fatigue Life Physics and Modeling |

|

2020 |

NASA |

Phase II |

STTR |

T12 |

A Multiscale Modeling Suite for Process and Microstructure Prediction in Metal Additive Manufacturing |

|

2019 |

Department of Defense |

Phase II |

SBIR |

A17-003 |

Development of In-Process Monitoring Closed-Loop Feedback for Use in Aluminum Alloy Additive Manufacturing (AM) Applications |

|

2018 |

NASA |

Phase I |

STTR |

T12 |

A Multiscale Modeling Suite for Process and Microstructure Prediction in Metal Additive Manufacturing |

|

2018 |

Department of Defense |

Phase I |

STTR |

N18A-T005 |

Innovative Processing Techniques for Additive Manufacture of 7000 Series Aluminum Alloy Components |

|

2017 |

Department of Defense |

Phase II |

SBIR |

N152-109 |

Reliability Centered Additive Manufacturing Design Framework |

|

2017 |

Department of Defense |

Phase I |

SBIR |

A17-003 |

Development of In-Process Monitoring Closed-Loop Feedback for Use in Aluminum Alloy Additive Manufacturing (AM) Applications |

|

2017 |

Department of Defense |

Phase II |

SBIR |

DLA-152-001 |

Advanced Manufacturing Technologies |

|

2016 |

Department of Energy |

Phase II |

SBIR |

9.01.06.73-R |

Predictive Modeling Tools for Metal-Based Additive Manufacturing |

|

2016 |

Department of Defense |

Phase I |

SBIR |

N152-109 |

Reliability Centered Additive Manufacturing Design Framework |

|

2015 |

Department of Defense |

Phase I |

SBIR |

DLA-152-001 |

Advanced Manufacturing Technologies |

|

2015 |

Department of Energy |

Phase I |

SBIR |

9.01.06.73-R |

Apply Modelica Language to Multi-physics Applications on HPC and Cloud Platforms |

|

2015 |

Department of Energy |

Phase I |

SBIR |

9.01.06.73-R |

Predictive Modeling Tools for Metal-Based Additive Manufacturing |

|

2014 |

Department of Defense |

Phase I |

STTR |

N14A-T019 |

Bioelectronic Fusion Sensor System |

|

2014 |

Department of Defense |

Phase I |

SBIR |

AF141-075 |

Improved Design Package for Fracture Mechanics Analysis |

|

2013 |

National Science Foundation |

Phase II |

SBIR |

NM-1330900 |

SBIR Phase II: Analytical Modeling and Performance Prediction of Remanufactured Gearbox Components |

|

2013 |

Department of Defense |

Phase II |

STTR |

N11A-T007 |

Modeling to Quantify Improved Durability of Superfinish Gear Processing |

|

2012 |

Department of Defense |

Phase I |

SBIR |

A12-076 |

Advanced Seal Technology for Helicopter Drive System Application |

|

2012 |

Department of Defense |

Phase I |

SBIR |

A12-098 |

Multi-functional Integrated Drive System Sensor(MIDSS) for Rotorcraft |

|

2012 |

Department of Defense |

Phase I |

SBIR |

A12-022 |

Surface Engineering Technologies for Improved Gear Efficiency |

|

2012 |

National Science Foundation |

Phase I |

SBIR |

NM-1215280 |

SBIR Phase I: Analytical Modeling and Performance Prediction of Remanufactured Gearbox Components |

|

2012 |

Department of Defense |

Phase I |

STTR |

N12A-T010 |

Developing and validating a model to understand mixed lubrication regions for fluid-film bearings |

|

2012 |

Department of Defense |

Phase II |

SBIR |

A10-169 |

Fatigue Crack Initiation Prediction Tool for Rotorcraft Spiral Bevel Gears |

|

2011 |

Department of Defense |

Phase I |

STTR |

N11A-T007 |

Modeling to Quantify Improved Durability of Superfinish Gear Processing |

|

2011 |

Department of Defense |

Phase II |

SBIR |

N101-006 |

Prognostic & Health Management (PHM) Technologies for Unmanned Aerial Vehicles (UAV)Optimized PHM System for Unmanned Aerial Vehicles |

|

2011 |

Department of Defense |

Phase II |

SBIR |

N093-170 |

Spline Health Prognosis via Physics Based Modeling Coupled with Component Level Tests |

|

2010 |

Department of Defense |

Phase I |

SBIR |

A10-169 |

Fatigue Crack Initiation Prediction Tool for Rotorcraft Spiral Bevel Gears |

|

2010 |

Department of Defense |

Phase II |

SBIR |

AF073-135 |

Vibration Analysis of Rotating Plant Machinery |

|

2010 |

Department of Defense |

Phase II |

SBIR |

N091-017 |

Gearbox Load and Life Simulation Software |

|

2010 |

Department of Defense |

Phase I |

SBIR |

N101-006 |

Prognostic & Health Management (PHM) Technologies for Unmanned Aerial Vehicles (UAV)Optimized PHM System for Unmanned Aerial Vehicles |

|

2010 |

NASA |

Phase I |

SBIR |

A209 |

Enhanced Prediction of Gear Tooth Surface Fatigue Life |

|

2010 |

Department of Defense |

Phase I |

SBIR |

N093-170 |

Spline Health Prognosis via Physics Based Modeling Coupled with Component Level Tests |

|

2009 |

Department of Defense |

Phase I |

SBIR |

N091-017 |

Gearbox Load and Life Simulation Software |

|

2008 |

Department of Defense |

Phase I |

SBIR |

N08-122 |

Advanced Intelligent Web-Based Options to Acquire and Analyze Aircraft Health and Test Data |

|

2008 |

Department of Defense |

Phase I |

SBIR |

AF073-135 |

Vibration Analysis of Rotating Plant Machinery |

|

2007 |

Department of Defense |

Phase II |

SBIR |

N06-023 |

Automated Reasoner Technology for Managing Military Aircraft |

|

2007 |

Department of Defense |

Phase II |

SBIR |

AF06-094 |

High Performance Cage Sensors for Rolling Element Bearing Health Monitoring |

|

2007 |

Department of Defense |

Phase II |

SBIR |

AF06171 |

Health Management for Gas Turbine Engine Accessory Components |

|

2007 |

Department of Defense |

Phase II |

SBIR |

N05-094 |

Embedded Health Monitoring for Propulsion Control System Actuators |

|

2007 |

NASA |

Phase II |

SBIR |

A104 |

Model Updating in Online Aircraft Prognosis Systems |

|

2006 |

Department of Defense |

Phase I |

SBIR |

N06-108 |

Cognitive Technology for Advanced Maintenance |

|

2006 |

Department of Defense |

Phase I |

STTR |

N06-T007 |

Aircraft Electrical Power System Diagnostics and Health Management |

|

2006 |

NASA |

Phase I |

SBIR |

05-II A1.04 |

Model Updating and Uncertainty Management for Aircraft Prognostic Systems |

|

2006 |

Department of Defense |

Phase I |

SBIR |

AF06-094 |

High Performance Cage Sensors for Rolling Element Bearing Health Monitoring |

|

2006 |

Department of Defense |

Phase I |

SBIR |

N06-023 |

Automated Reasoner Technology for Managing Military Aircraft |

|

2006 |

Department of Defense |

Phase I |

SBIR |

AF06-171 |

Health Management for Gas Turbine Engine Accessory Components |

|

2006 |

NASA |

Phase I |

SBIR |

A104 |

Model Updating in Online Aircraft Prognosis Systems |

|

2005 |

Department of Defense |

Phase II |

SBIR |

A04-077 |

Prognostic Wear Prediction Tool for BlackHawk Hanger Bearings |

|

2005 |

Department of Defense |

Phase I |

SBIR |

N05-104 |

Effective Diagnostics for Dynamic Operating Environments |

|

2005 |

Department of Defense |

Phase I |

SBIR |

N05-089 |

Innovative Materials/Concepts for Grease Lubricated Bearings |

|

2005 |

Department of Defense |

Phase II |

STTR |

MDA04-T022 |

Strategic Monitoring of Spacecraft Mechanical Parts Assemblies |

|

2005 |

Department of Defense |

Phase I |

SBIR |

N05-094 |

Embedded Health Monitoring for Propulsion Control System Actuators |

|

2005 |

Department of Defense |

Phase II |

SBIR |

N04-028 |

Validation Tools and Data for PHM Technologies |

|

2005 |

Department of Defense |

Phase I |

SBIR |

AF05-188 |

Methodology for the Real-Time Management of Aero Gas Turbine Engine Usage Data |

|

2005 |

Department of Defense |

Phase I |

SBIR |

A04-077 |

Prognostic Wear Prediction Tool for BlackHawk Hanger Bearings |

|

2004 |

Department of Defense |

Phase I |

STTR |

MDA04-T022 |

Strategic Monitoring of Spacecraft Mechanical Parts Assemblies |

|

2004 |

Department of Defense |

Phase I |

SBIR |

N04-028 |

Validation Tools and Data for PHM Technologies |

|

2004 |

Department of Defense |

Phase II |

SBIR |

N02-195 |

Fault-to-Failure Progression Modeling of Propulsion System and Drive Train Bearings for Prognostic and Useful Performance Life Remaining Predictions |

|

2002 |

Department of Defense |

Phase I |

SBIR |

Fault-to-Failure Progression Modeling of Propulsion System and Drive Train Bearings for Prognostic and Useful Performance Life Remaining Predictions |