Wind turbine drivetrain system failures plague the industry with unplanned downtime and expensive repairs. According to the National Renewable Energy Lab, 64% of drivetrain failures are caused by bearing damage and wear.

White etch cracks (WEC) in bearings cause microstructural alterations that result in different crack morphology and varied failure mechanisms that lead to major system failures within wind fleets.

Research has been completed by scientists on why WEC formation occurs in bearings, but a definitive reason for why WEC formation occurs in bearings continues to be debated.

Sentient Science partnered with a major wind operator in the United States to examine microstructural alterations in low-speed intermediate shaft and high-speed intermediate shaft bearings from failed gearboxes.

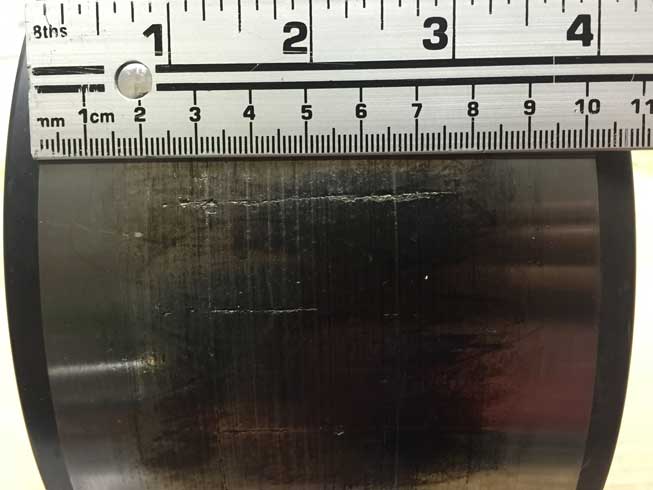

During the analysis, butterfly wing formations were detected in LSIS bearings around nonmetallic inclusions, which were accompanied by circumferential cracks at depths greater than 300 Im. Irregular WEC was found in the HSIS bearings with random crack orientations. The findings supported existing hypothesis that white etch areas precede crack formations and cracks are prerequisites for white etch formation.

The analysis and data collected is enabling Sentient Science to develop materials science-based prognostic life prediction models that link WEC and butterfly wing qualitative observations in turbines with real operating conditions, bearing design and manufacturing process.

A webinar on the progress Sentient has made on developing capabilities to predict WEC formation will be held Wednesday, Aug. 23 at 1 p.m. EST.