Case Studies

An Integrated Computational Materials Engineering Predi …

Additive manufacturing (AM) processes create material directly into a functional shape. Often the material properties…

Read More

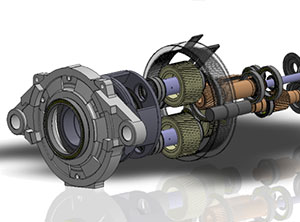

50% Reduction in Gearbox Replacements

DC-OM Helped One Customer Reduce the Number of Gearbox Replacements by 50% Moving from Unplanned…

Read More

Materials Science Lab

Materials Science Models The operational life of complex rotating equipment does not always match…

Read More

How to Lower the Cost and Risk of LTSAs and FSAs

Introduction Long term service agreements (LTSAs) are often an attractive asset management strategy for…

Read More

The Value of the Elusive ‘Golden Bill of Materials’ …

The standard configuration of a wind turbine gearbox may not match the…

Read More

Duke Energy Invests in Digitalization to Reduce Costs & …

Duke Energy Renewables’ decided to self-operate its wind turbine fleet with an estimated cost savings of up to 35% from shifting to…

Read More

GE 1.5 Extra Life Gearbox Achieves 4x Life

Premature failures in the GE 1.5 gearboxes are driving unexpected downtime and increased costs. The industry is seeking solutions to…

Read More

Analyzing the Life Impact of REWITEC® DuraG …

Wind turbine operators are seeking a solution to extend the life of their gearboxes that are failing prematurely. REWITEC® developed…

Read More

Evaluation of High Speed Bearing Life Extension with Ae …

Aerotorque WindTC shown to reduce overload and torque events that can lead to white etch area formation by 4x. High…

Read More

Boeing Designs and Maintains Next Generation Rotorcraft …

The U.S. Army and Boeing are deploying new prognostic gearbox health assessment technologies to optimize life and performance while minimizing…

Read More