New Standard Accelerates Digitalization Efforts of Wind Industry

Often times digitalization is implemented within an organization without clear understanding of how digital tools can be used to address problems and generate business value.

For example, the first wave of digitalization involved digitizing the standard SCADA streams of data to support pro-active maintenance and performance monitoring to help reduce Levelized Cost of Energy (LCOE). To date, even the most progressive wind operators have hit a glass ceiling around the benefits that come from centralizing the SCADA streams because the outputs are only focused on a handful of business problems.

With the phase down of government subsidies, a new wave of digitalization is required to achieve additional LCOE savings to cover the $1.3 billion of lost revenue over the next 10 years from Production Tax Credits. Software, such as Sentient’s DigitalClone, utilize new data streams to enhance long-term forecasting and predictive maintenance, providing life extension decision tools, reduction in costs for asset and risk management, and supply chain optimization.

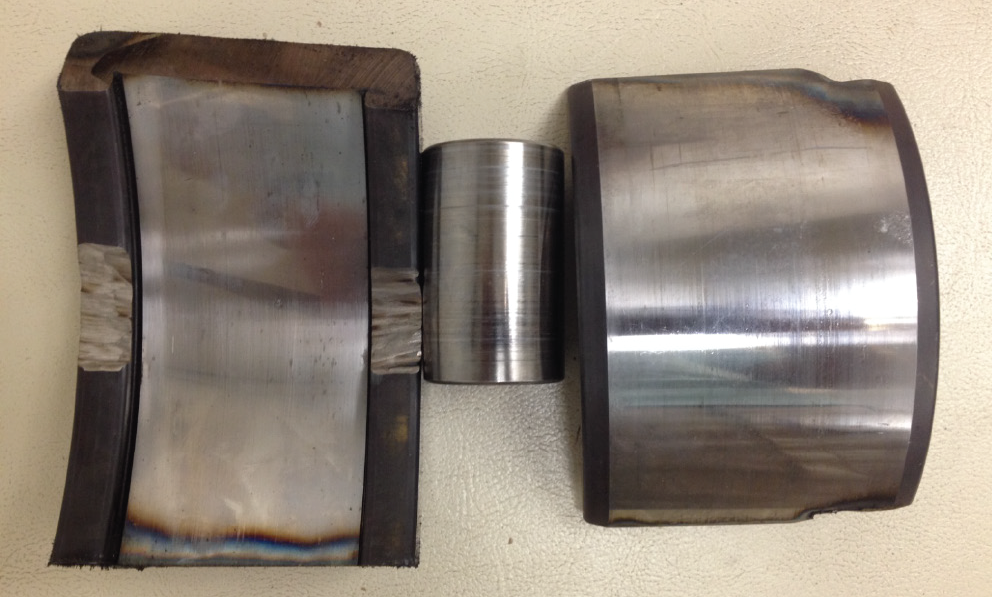

This new era of digitalization requires a focus on previously undervalued data sources. One such data source is field inspection results of the bearings and gears in the drivetrain – main bearings, gearbox components, generator components and pitch systems.

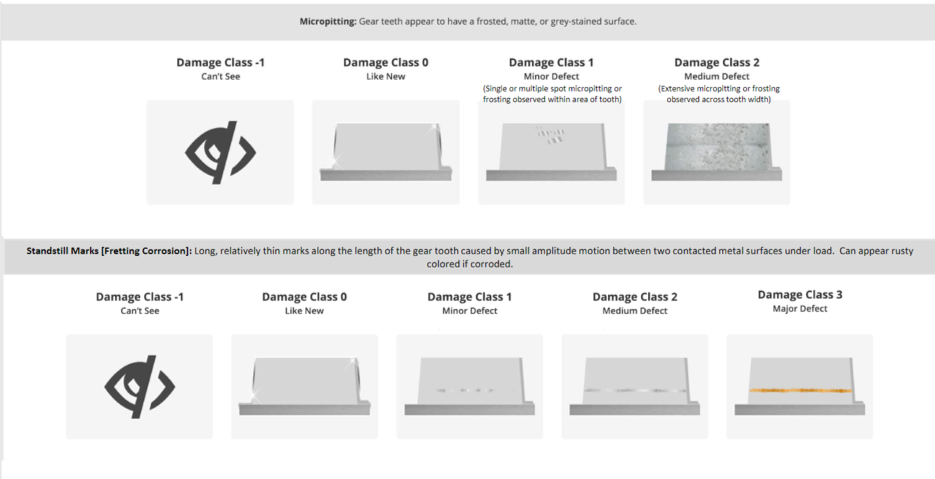

A lack of common measurement [standardization] for damage class and damage mode of respective major components and their sub-component locations becomes problematic when integrating digital solutions. Often, for those who have an internally defined damage classification system, these systems are defined in such a way as to define ‘risk’ of component failure. These risk measurements are made on past field experiences translated into “gut feelings”. These practices, while valuable, lack uniformity, scalability and repeatability across the organization, site by site and even within personnel.

To truly define failure risk of a damaged component, a combination of inputs is needed, including damage mode, damage class, sub-component location, turbine operation, and turbine load during operation, among others.

Leveraging Sentient’s customer base of more than 20,000 live assets and team of materials scientists, mechanical engineers, and tribologists, we have developed a damage classification standard for bearings and gears to seamlessly convert field results into digital format. The output:

- Creates clear separation of damage state from risk of failure

- Reduces the burden of digitalization through streamlined reporting processes at the source

- Empowers inspection technicians to categorize damage state and mode on site

- Enables the use of precise damage progression models to assess failure risk for field work allocation, scheduling and budgeting

Example of damage gear damage class modes from the Sentient standards document

The standard is public and available here.

Digitalization platforms should provide the framework necessary to create rich datasets (including field observations above) that minimize noise and ambiguity for physics models, artificial intelligence, and machine learning algorithms to consume. Noise and ambiguity have the potential to prevent any model from producing valuable results. Higher model precision from uniform standards of damage mode and classification range enables field decisions that lead to economic value within the organization.

For information on the Damage Classification Standards, reach us at contact@sentientscience.com