Challenge

Wind turbine operators are seeking a solution to extend the life of their gearboxes that are failing prematurely. REWITEC® developed DuraGear® W100 of nano and micro-particle based lubricant additives treatment to improve performance and life extension in gearboxes. Over the years the company proved its capability to reduce surface roughness on bearings and gears in wind turbine eld trials and tests, however, REWITEC® was challenged to how best use the treatment on gearbox components to maximize the return on investment of their customers.

Scope of Work

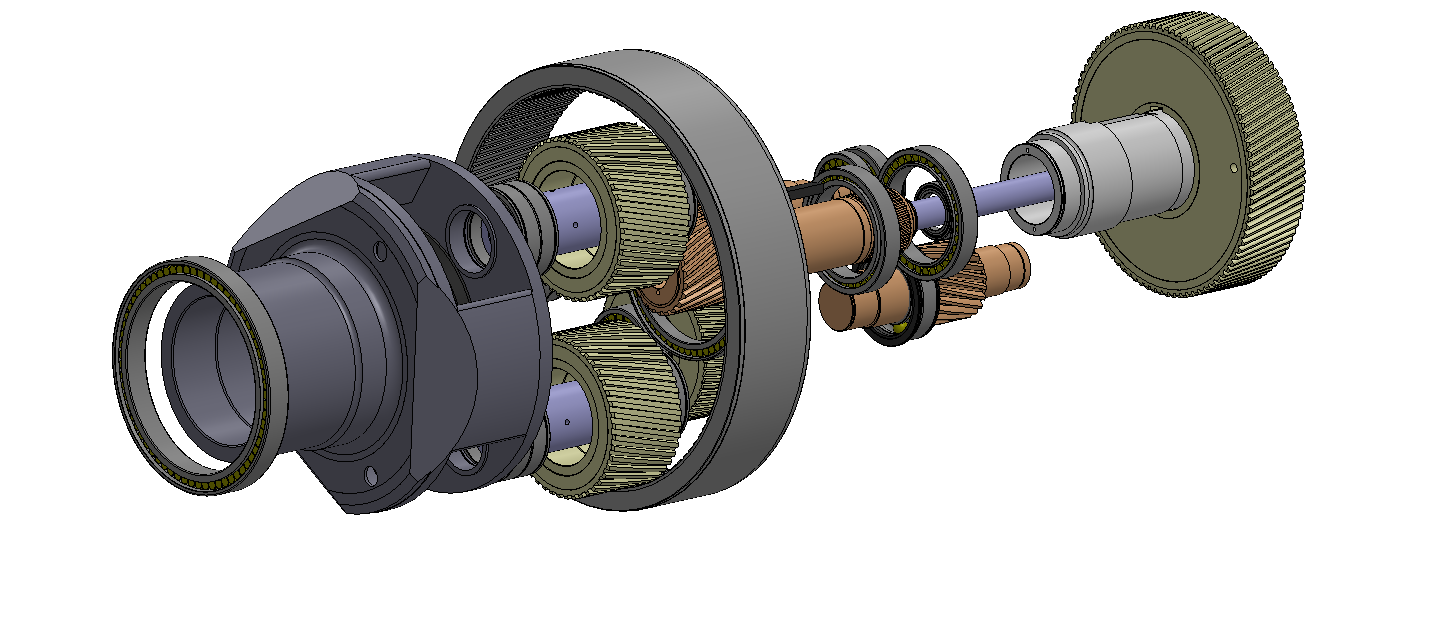

REWITEC® contracted Sentient Science to use its DigitalClone® technology to predict and compare the contact fatigue life of key gear and bearing components with field measured surface roughness inputs from Winergy 4410.2 gearboxes before and after REWITEC’s DuraGear® W100 treatment.

Result

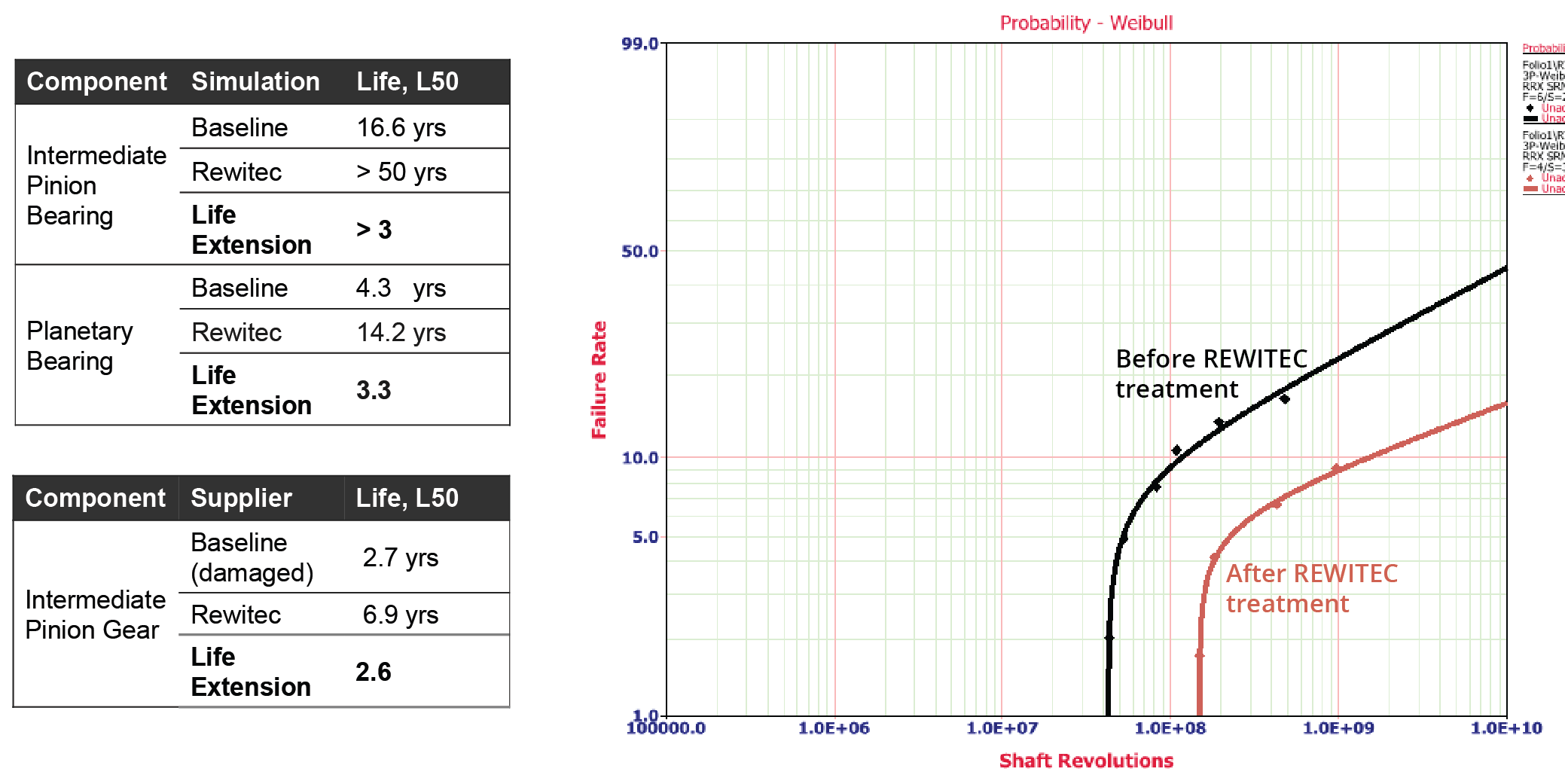

Sentient Science developed a material-science based predictive model of a GE 1.5 SLE Winergy 4410.2. This DigitalClone® gearbox model was used to study the fatigue life impact of W100 treatment on surface damaged bearings and gears. As a result of the measured reduction in surface damage due to the W100 treatment, Sentient’s DigitalClone® technology predicts that Winergy 4410.2 gearboxes will exhibit a significant improvement in life compared to untreated gearboxes – under field representative operating conditions, REWITEC’s DuraGear® W100 treatment is calculated to improve bearing life by a factor of 3.3 and overall gear life by a factor of 2.6. The effect of REWITEC DuraGear® W100 on gearbox performance is greater for relatively smooth bearing and gear surfaces with small pits and wear, supporting the application of DuraGear® W100 in the early stages of bearing and gear damage for better life improvement. Fleet and asset-specific return on investment calculations can be performed with wind turbine operators who have deployed DigitalClone® Live.

Material Model Development |Based on Winergy 4410.2 material analysis

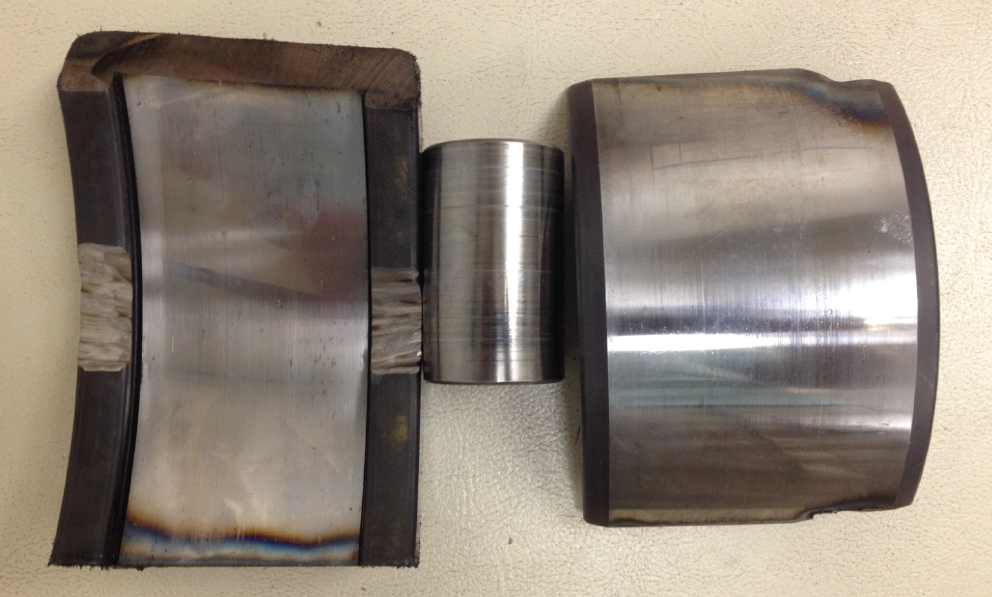

Material characterization work was performed by Sentient on gear and bearing segment samples to obtain microstructure data that served as the input into the DigitalClone® material model. These characteristics included grain size, case and core microstructure, defect area fraction, retained austenite, grind burn, among others. Gear and bearings evaluation also included residual stress analysis and surface roughness analysis.

Procedure & Assumptions

REWITEC® performed a variety of tests to validate the effect of their DuraGear® W100 treatment in bearings and gears. FE-8 bearing tests were performed at the University Mannheim of Applied Science with Castrol X320 oil. Also, mini FE-8 bearing tests were done at the University Giessen with Castrol X320. REWITEC also provided results of field tests showing surface roughness in gear flanks with and without REWITEC®. These gear field tests were performed on Winergy 4410.2 with Castrol X320 and Bosch Rexroth with Castrol A320.

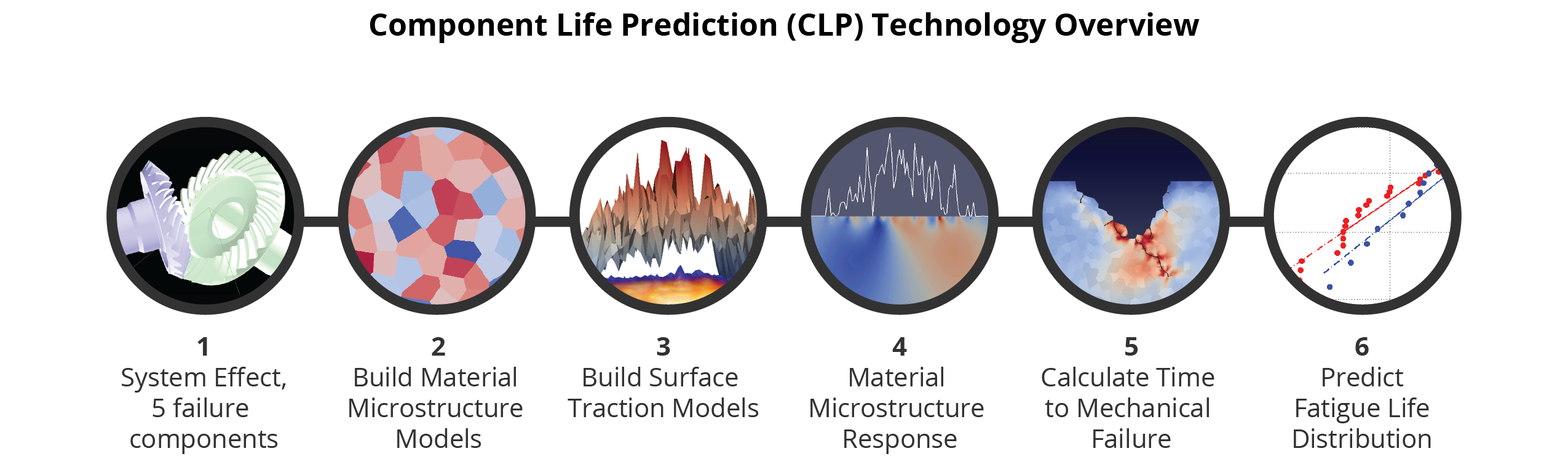

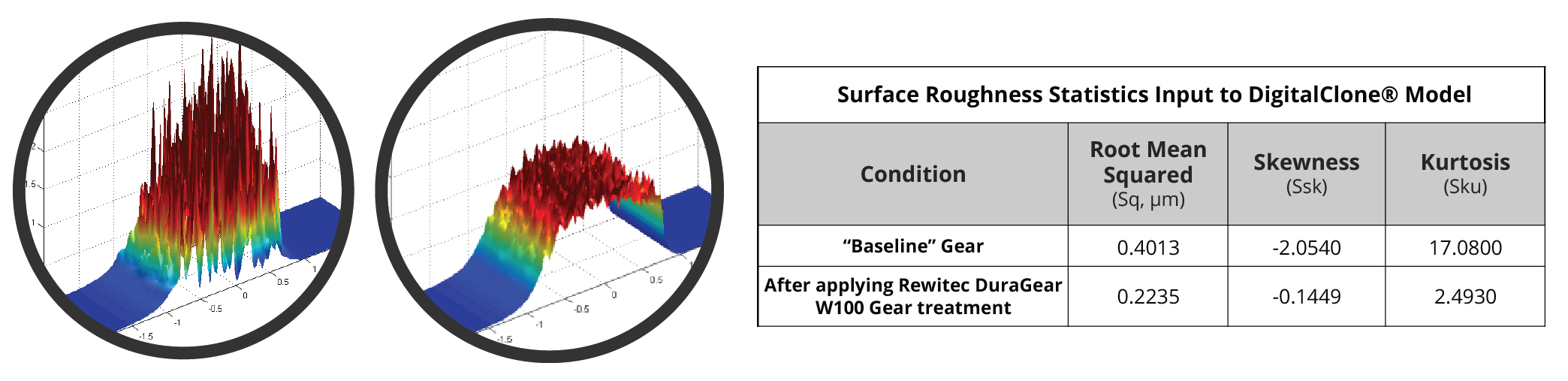

Using the REWITEC® provided specific gear and bearing surface roughness measurements with and without treatment, Sentient ran two cases for each of several critical components (intermediate pinion bearing, planetary bearing, and intermediate pinion gear). Aside from the surface roughness differences Sentient assumed that all other model input parameters including bearing and gear loads, metallurgical and material properties, and oil viscosity remained unchanged from Sentient’s Winergy 4410.2 prognostic model. Sentient used its proprietary six-step prognostic modeling process to evaluate life of the two different surface finishes. REWITEC® used these tests to provide Sentient Science with the surface finish data of the components with and without REWITEC DuraGear® W100 treatments.

Mixed-EHL Solution for Life Prediction

To take the influence of microasperity into account for determination of probablistic fatigue life, Sentient mixed EHL (elastrohydrodynamic) solver utilizes simulated surface roughness profiles in an explicit-deterministic calculation of surface tractions. Surface traction refers to the pressures transmitted between two surfaces through a lubricant.

The plots on the right illustrate the surface pressure of two such modeled rough surfaces interacting (left) and two [DuraGear® treated] smooth surfaces interacting (right).

Result

DigitalClone® predicts that a Winergy 4410.2 damaged gearbox treated with REWITEC DuraGear® W100 has a significant improvement in life than untreated gearbox under representative turbine operating conditions. Specifically, for bearings, REWITEC’s DuraGear® W100 treatment is expected to improve the overall contact fatigue life by a factor of 3.3. For gears, REWITEC’s DuraGear® W100 treatment is expected to improve the overall fatigue life by a factor of 2.6.

About REWITEC

Founded in 2003, the technology company has set itself the task of promoting the longevity and energy efficiency of systems, machinery and gearboxes. With the development of nano- and micro-particle based lubricant additives, REWITEC® focuses on the sustained running time of treated engines and gearboxes and would thus like to make a considerable contribution to energy friendliness. With the objectives of protecting investments against wear and excessive energy consumption and achieving system security and ease of repair, the medium-sized lubricant specialist REWITEC® markets its solutions worldwide. In terms of its own development, however, the independent company attaches great importance to high-quality production in Germany. For this reason, the entire research, development and production takes place at its headquarters in Lahnau.