Everyone talks about predictive maintenance as a way to improve efficiencies and reduce costs. However, there’s been little movement in moving from corrective maintenance to predictive maintenance practices in the aerospace industry.

You see, there’s a big difference between maintenance and sustainment. Improving maintenance efficiencies, can help achieve maybe 1% to 2% savings on costs through big data solutions. However, when looking at optimizing the performance of the asset through life extension actions, materials science is needed, in addition to data science, to paint a clearer picture of the entire spectrum of the asset’s lifecycle and associated costs. When data is provided on the short, medium and long-term failure rates of the asset, an operator can actually achieve 13% or more savings on the cost of revenue.

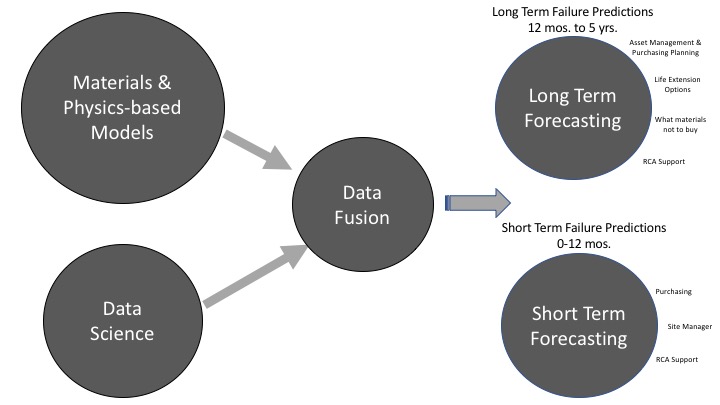

Our software complements the entire lifespan of the asset from design/conception phase to monitoring the health and life extension of the asset during operation. Sentient Science’s DigitalClone software simulates how the materials perform and respond to the operational conditions experienced in the field. These physics-based simulations combine the materials-based models with data science models to predict the failure rates of the drivetrain and critical components.

When monitoring the live asset, the user receives a watchlist of the failures occurring today, and the failure rates of the major systems and critical components predicted to occur in the next 12 months to 5+ years. Based on the data provided, decisions can be made like how to operate the helicopter to optimize maintenance schedules; which aftermarket parts offer the greatest return on investment; and what was the root cause of a failure that occurred to argue a warranty or insurance claim.

Sentient Science’s unique approach to digitalization is about more than just optimizing operations and maintenance. It’s a business strategy that enables efficiencies in all departments and aspects of an organization. When knowing the long-term health of the asset at the system and critical component level, decisions can be made to optimize asset performance, improve supply chain efficiencies and reduce risk.

Next week, we’ll be at the HAI Heli-Expo Conference in Las Vegas, NV, leading discussions on digitalization. Our technical team will be hosting live presentations every hour in our booth #C3245, in the first-time pavilion. On Wednesday, at 1:30 p.m., we’ll also participate in Rotor & Wing International’s panel discussion on “How Digitalization is Transforming the Aerospace Industry.” We’re joined by CHC, Bell Helicopter, Uber Elevate and Honeywell.

Schedule time to meet our team here.