Original equipment manufacturers (OEMs) in almost every industrial industry are investing heavily into metal Additive Manufacturing programs (AM), but struggle to release functional components into the market. OEMs continue the investment, however, because AM processes demonstrate enormous potential for rapid, art-to-part capability for high value, complex and customizable parts.

The Struggle is Real

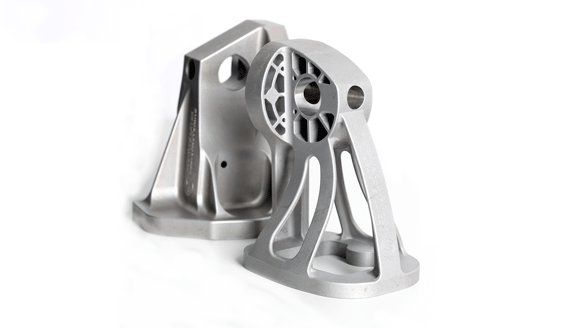

A metal AM part may take several days to build. However, a defect early in the layering process could doom the part to failure before it’s even grown. Even worse, the designer typically has no idea that there’s a fault during manufacturing until the part is built and there’s a crack in the microstructure or the part distorts. With no warning that there may be a defect in the material during the layering process, AM engineers are literally doing trial and error to find the optimal recipe.

Precious time, money and resources are spent designing the component, growing the component, then reverse engineering failed components to determine when in the layering process the defect occurred. Rinse. Recycle. Repeat.

Materials Science & Physics-based Modeling

Sentient Science’s DigitalClone technology is materials science and physics-based modeling software simulating:

- Design growth

- Predicting life of the AM part under real operating loading conditions

- Comparisons of AM part vs. conventional manufacturing options

Using DigitalClone, we’ve developed a Quality Operating System (QOS) to evaluate the quality and reliability of AM parts through the design to production process, streamlining new product development in order to get more high quality AM parts into the market.

How it works…

Cracks and other part failures often occur during the build from the intense temperature gradients that occur from the internal welds of each layer.

During the simulation process, DigitalClone for Additive Manufacturing considers:

- Machine parameters to reduce the variability between machines and materials

- Material properties to compare powders

- Part geometry to assess producibility early in the design cycle

- Support structures to identify the optimal placements and removal

- Mechanical loading to assess lifecycle costs

DigitalClone is able to predict and recommend changes where high probability of failure is located within the material microstructure of the AM component.

In order to predict and identify risk, DigitalClone for Additive Manufacturing simulates temperature, residual stress, distortion, melt pool, porosity, grain structure and fatigue life.

During simulation, DigitalClone considers:

- power density

- scan speed

- hatch strategy

- layer thickness

- laser beam dimension

- pre-heat temperature

- material properties

- geometry and layout

- support structure

- cyclic loading type/magnitude

The software predicts design life at specific loading conditions, saving engineering time and cost of re-prototyping. If there’s distortion or thermal stress identified, the designer is able to rapidly analyze multiple design/material alternatives to accelerate the design and qualification process.

The software answers these main questions:

- Will the design grow or will it fail?

- Where is the failure and failure type located in the microstructure?

- How long it this AM part last under actual operating conditions?

To learn more about DigitalClone for Additive Manufacturing or to schedule a demonstration.