Physics. Digitalization. Life Extension.

DigitalClone® Software predicts the short and long-term failure rates of mechanical systems like additively manufactured parts, automotive, wind turbines and rotorcrafts to identify life extension actions that reduce cost.

Request Demo

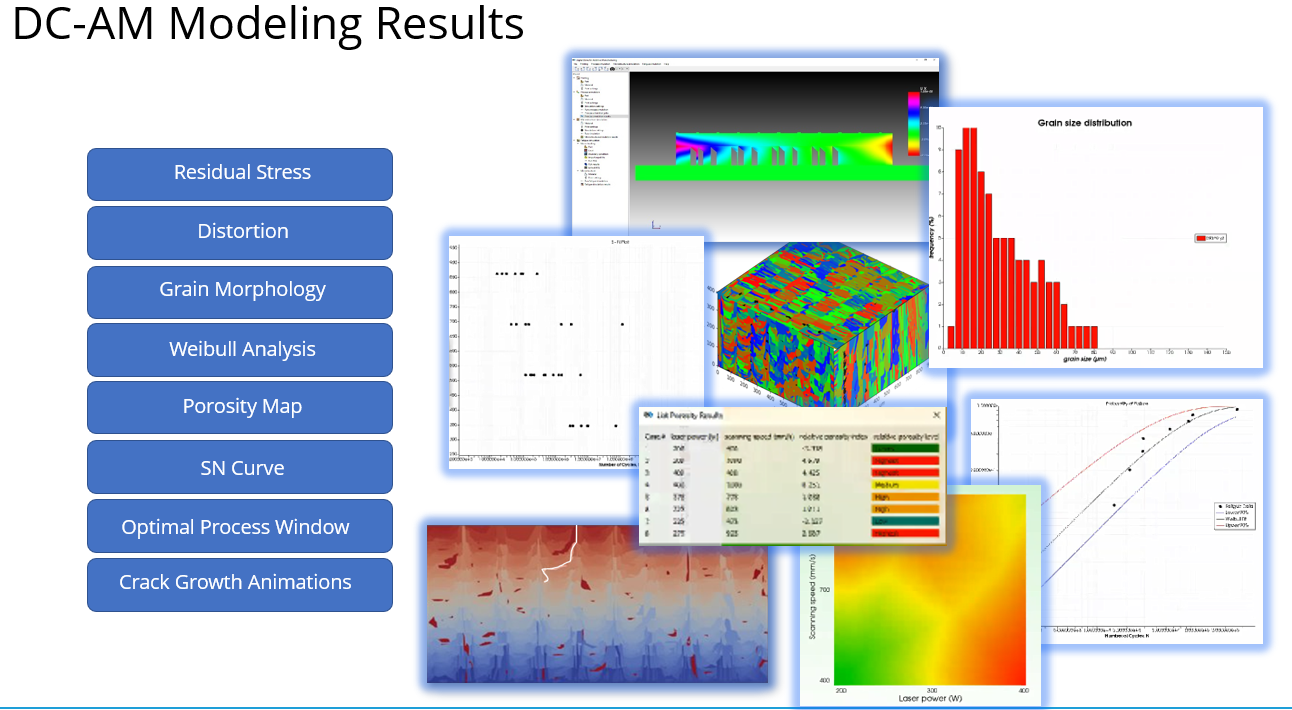

for Additive Manufacturing

DC-AM is a physics-based ICME platform that links process-microstructure-fatigue performance for metal additive manufacturing that virtually examines AM parts at microscale level, including grain size, grain morphology, porosity. Customers indicate that DC-AM can reduce iterations for design optimization by 75% and decrease cost for AM part qualification by up to 50%.

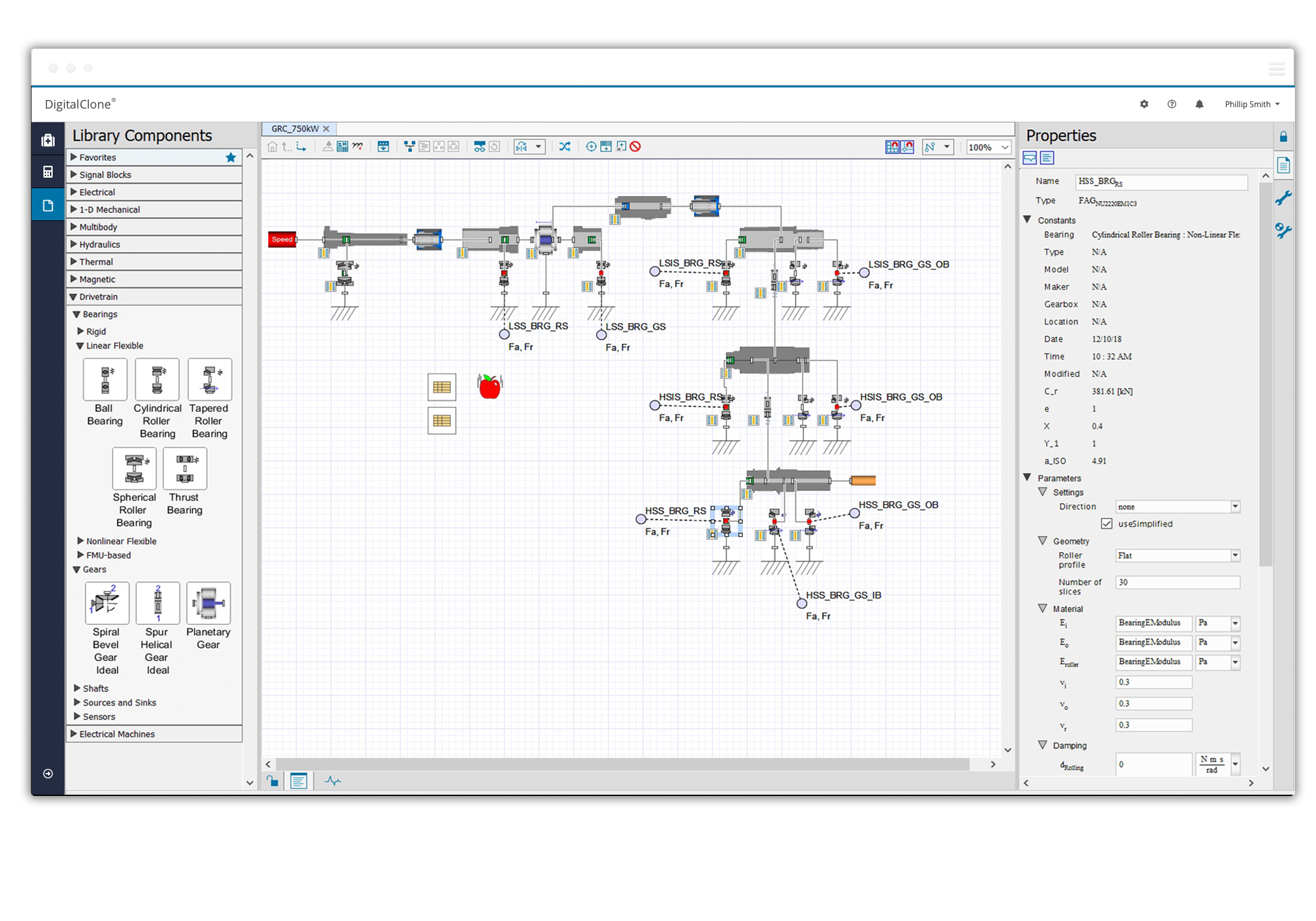

for Engineering

DC-E is a multi-body dynamics digital twin that uses physics-based models to make statistical life predictions of drive train components. It is the world’s only integrated solution from system modeling to bearing and gear detailed analysis to simulation-based component life prediction. No other solution incorporates microstructure-based life predictions. Customers using this technology have achieved up to 35% cost savings and 65% schedule compression for drive system development programs.

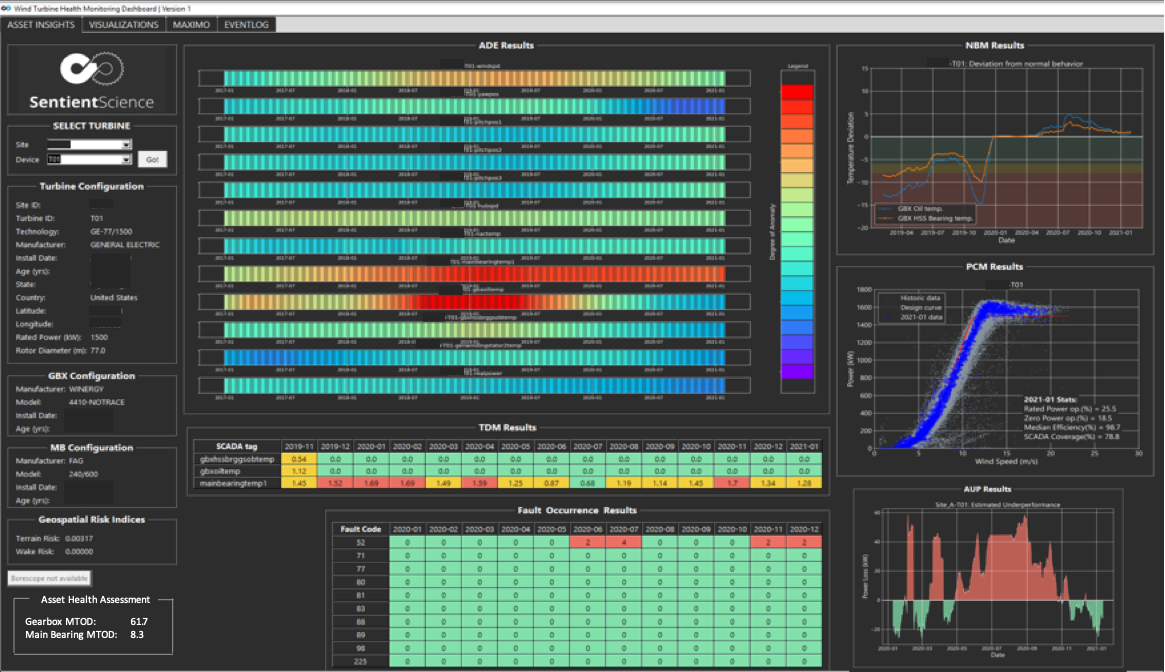

for Wind Operations & Maintenance

DC-OM is a digital twin of two major individual turbine major components at scale, gearbox and main bearing, using machine learning to deliver health prediction capability superior to CMS. A unique orchestration functionality is under development to host 3rd party health prediction models for other individual turbine major components at scale such as blades, towers, hub, etc. to provide a holistic management of a wind turbine.

DigitalClone Uses Physics to Predict the Life of Major and Minor Components for Life Extension

DigitalClone predicts the life of complex rotating equipment. The software builds materials-based models and simulates how the unique loading conditions and operational events impact the long-term reliability of the major systems and critical components. Both operators and suppliers in the electrification and transportation markets use the software for its materials science-based computational testing.

Awards