Driving efficiencies through digital data is important. However, when its reliant on sensor data only to detect anomalies and trends that alert to an impending failure, the operator cannot achieve efficiency savings above 1% to 2%. That’s because standard operating procedure remains rooted in corrective maintenance practices, resulting in costly repairs and downtime.

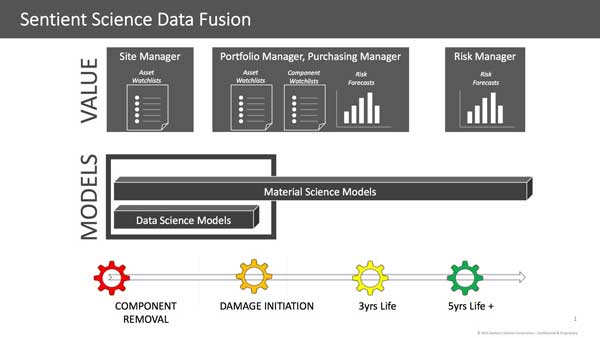

The best way to achieve optimal savings of more than 13% is by combining materials science and data science to develop a watchlist for advanced planning, forecasting and budgeting. This can only be achieved by understanding short, medium and long term failure rates for the fleet’s major systems and components in the field. This data goes years beyond the standard 12-18 month life predictions provided in data science solutions. Our watch lists provide the failures occurring today, the failure rates over the next 12-60 months, and 5+ years.

When you look at the science behind why failures occur, digitalization becomes a business strategy, and not a technology strategy. There’s an important difference, because it goes beyond driving operations and maintenance efficiencies. This level of data, enables long-term planning for asset management, supply chain efficiencies that result in reductions in safety stock, root cause analysis for warranty and insurance claims and risk exposure analysis on mergers and acquisitions of wind farms.

Next week, the AWEA Operations & Maintenance Safety Conference will be held in San Diego. Our team will be on site to discuss our unique approach to digitalization. We will not be competing in the Shark Tank competition that questions if big data is truly a cost effective solution that will impact the bottom line. We are not a big data solution.

DigitalClone pairs materials science with data science to look at the root cause of failures. We understand how the materials are impacted by the loading conditions and degrade over time, so that we can control and prevent the failure from ever occurring through life extension.

Our technology approach unveiled a 68% difference in physical test data to live test data. That’s because you cannot test the impact of real operating conditions in a physical test lab. There are a multitude of outside variables that impact the true failure rates seen in the field. You need to create materials-based models that are computationally tested under the real operating conditions seen in the field to understand the true life of the asset.

To learn more about our technical approach, download whitepaper on main bearing analysis.