Digital Asset Management (DAM) is the process of creating a digital thread of physical assets, including the ability to organize, categorize, and search for events, activities and digital files at the touch of a computer button. It is tremendously beneficial for team strategies, not only marketing, but also engineering, manufacturing and other areas of technology.

These files may include images, documents and other forms of information that are valuable to their respective industries, and is vital that each person who needs access to these files has the ability to retrieve them anytime, anywhere. The end goal is to help improve the reliability and availability of physical assets, while increasing production levels and lowering costs.

DAM is increasingly important when introducing a new product innovation or design for an existing model. It helps reduce cost and time to market by increasing the data points and simulations of transient loading events that are representative to the field environment. It also makes sharing data much easier because of the self-serve access on the cloud. DAM aids the global need to access a large variety of data that supports the ever changing and increasingly high quality content. Virtual assets are being created and shared everyday, and with digital asset management, it makes access to information about them easier. The emerging digital revolution occurring in renewable energy, aerospace, rail, and transportation sectors undoubtedly see the benefits of creating digital threads for optimal asset management.

DAM provides a central location for all files, securely managing the information with the ability to instantly locate a needed file, saving industries a great deal of time. Furthermore, DAM enables industries to embed copyright information for every image and file in order to ensure privacy and contract rights. This lowers manual effort, relying more on artificial intelligence and data analytics.

Sentient Science’s DigitalClone® platform is based on material science technology, using advanced digitalization strategies to reduce the cost of flight hours for aerospace, cost of energy, and cost per ton mile. Since both customers and employees are located across the globe in locations such as Spain, China and the United States, it is essential that the critical information is accessible through digital asset management.

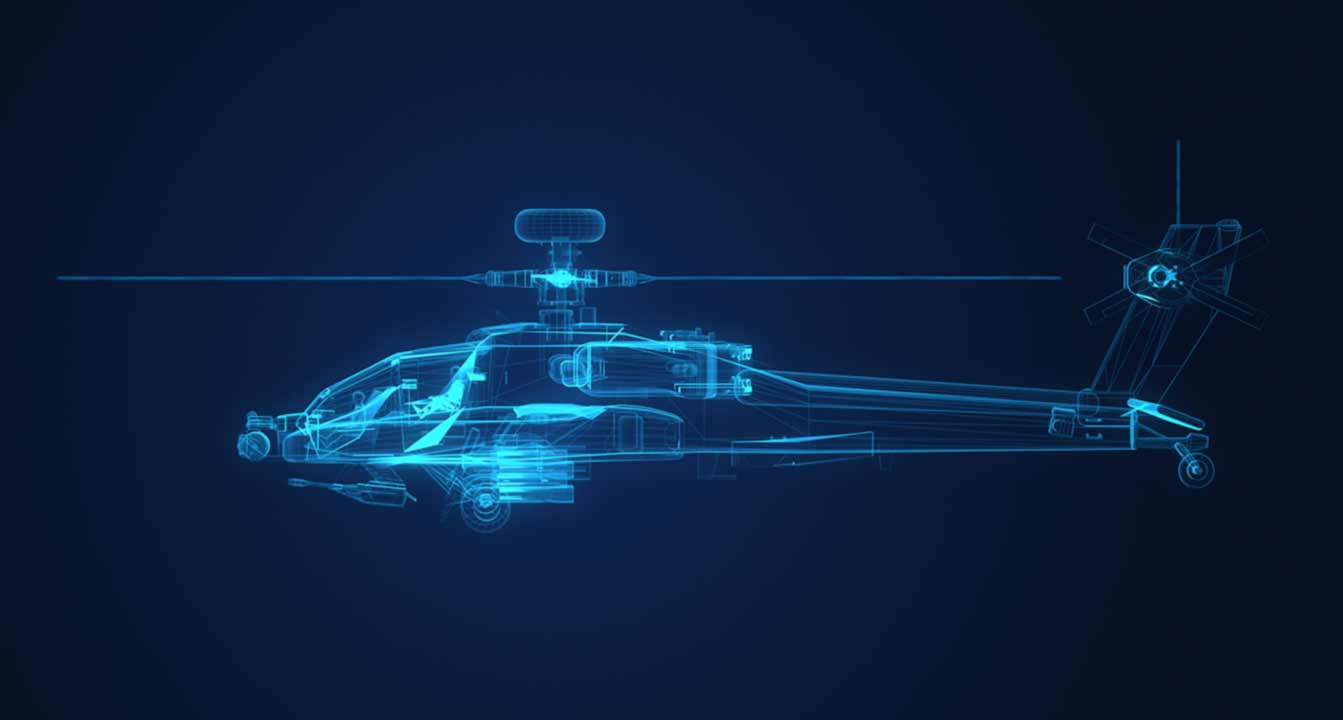

The DigitalClone platform enables customers to review status of their digitized helicopters, wind turbines or railroads, depending on the industry, including damage states, life extension options and optimal cost-saving opportunities within the contracted fleets. The platform also supports the upload, storage and viewing of images used to verify various damage states of subcomponents, such as micro pitting on the surface of gears, or scoring on bearing raceways, allowing maintenance personnel to visually track the progression of damage.

###

This article was written by Grace Wilson. Grace is an advertising & marketing major at Michigan State University and is interning at Sentient Science for the Summer of 2018.