Webinar Recordings

The Financial Impact of Extending Asset Life and Quanti …

Wind project finance is largely dependent on energy forecasts and energy uncertainty values to size…

Read More

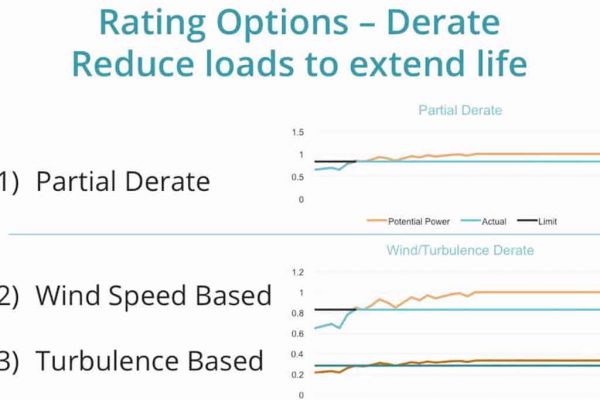

Life Extension Solutions: The Impacts of Uprating and D …

How can you know the impact of uprating and derating wind turbines? Today, most OEMs…

Read More

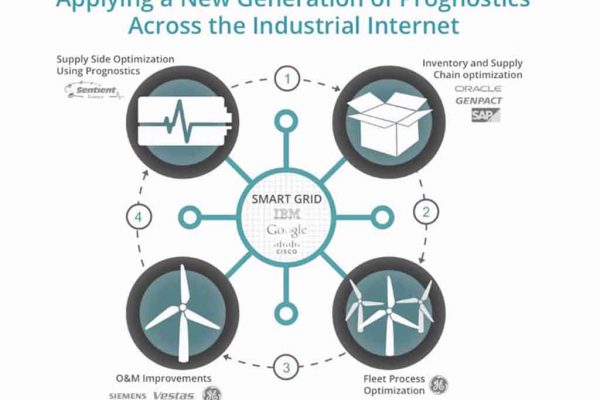

Applying a New Generation of Prognostics Across the Ind …

How is the Industrial Internet impacting corporate productivity today and in the future? Ed Wagner,…

Read More

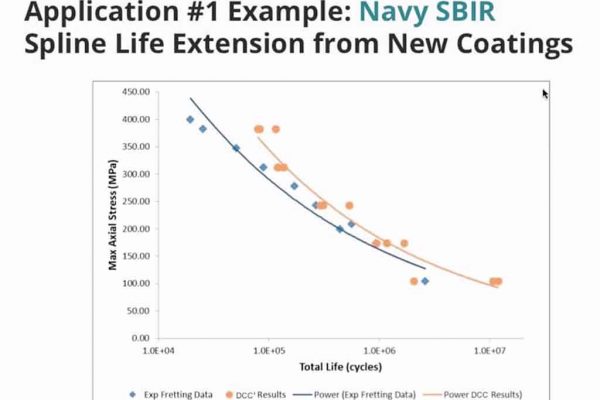

Gearbox Life Extension: Improving Rotorcraft Drivetrain …

With programs such as U.S. Army Future Vertical Lift (FVL), how can I predict rotorcraft…

Read More

Industrial Internet: Life Extension Solutions to Reduce …

At a recent Wind Energy Operations and Maintenance Summit (2014) Sentient Science’s CEO, Ward Thomas, and Amir Mikhail, PhD. talked about how O&Ms can take advantage of state-of-the-art life extension solutions and the industrial internet to reduce their wind turbine maintenance costs.

Read More

Multi-Physics Modeling: A Step By Step Approach to Pred …

When I request a Multi-physics DigitalClone model from Sentient Science, how exactly does their team…

Read More

Industrial Internet: Let’s Drive Deep into Wind ̵ …

Description: How can I be certain of the return on investment of my wind turbines…

Read More

Life Extension Solutions: Improving Gear Life and Perfo …

Description: What’s the best solution to extend the life of my gearbox system? Manufacturers and…

Read More

Improving Bearing Life and Performance with Computation …

Bearing manufacturers and their customers are seeking solutions to speed time-to-market of new products, increase…

Read More

Modeling of Complex Mechanical Systems

Description: Mechanical systems, like helicopter gearboxes, are built of many complex sub-systems that require many…

Read More